Carbon fiber sheets have revolutionized industries worldwide with their exceptional strength-to-weight ratio, durability, and corrosion resistance. As demand for lightweight yet robust materials grows, these sheets have become a go-to solution across sectors like aerospace, automotive, sports, and construction. In this article, we’ll dive into the top applications of carbon fiber sheets and why they’re a game-changer.

1. Aerospace and Aviation

Carbon fiber sheets are a staple in the aerospace industry. Their high tensile strength and low weight reduce fuel consumption and operational costs. Aircraft components such as wings, fuselages, and interior panels now incorporate carbon fiber to enhance performance and safety. Additionally, the material’s resistance to extreme temperatures and UV radiation makes it ideal for aerospace applications.

2. Automotive Engineering

From Formula 1 race cars to luxury vehicles, carbon fiber sheets are used to build chassis, body panels, and spoilers. Their lightweight properties improve fuel efficiency and acceleration, while their rigidity enhances handling. Car enthusiasts also opt for carbon fiber aftermarket parts to customize vehicles without compromising structural integrity.

3. Sports and Recreation

The sports industry leverages carbon fiber sheets for equipment that demands both power and precision. Tennis rackets, golf club shafts, bicycle frames, and hockey sticks benefit from the material’s stiffness and responsiveness. Carbon fiber’s ability to absorb vibrations also reduces athlete fatigue, making it a top choice for high-performance gear.

4. Marine and Boating

Marine applications require materials that withstand saltwater corrosion and harsh weather. Carbon fiber sheets are used in boat hulls, masts, and decking to reduce weight and increase speed. They also enhance stability, making them popular in racing yachts and luxury cruisers.

5. Construction and Infrastructure

In construction, carbon fiber sheets reinforce concrete structures to prevent cracks and improve load-bearing capacity. They’re also used in earthquake-resistant retrofitting and lightweight roofing systems. Architects and engineers appreciate their flexibility and long-term durability.

6. Consumer Electronics

High-end electronics like laptops, smartphones, and drones use carbon fiber sheets for sleek, durable casings. The material’s EMI shielding properties also protect devices from electromagnetic interference, ensuring optimal performance.

Why Choose Carbon Fiber Sheets?

- Lightweight: Up to 50% lighter than steel, reducing energy use.

- High Strength: Exceptional tensile strength for structural integrity.

- Corrosion-Resistant: Ideal for harsh environments.

- Design Flexibility: Customizable for complex shapes.

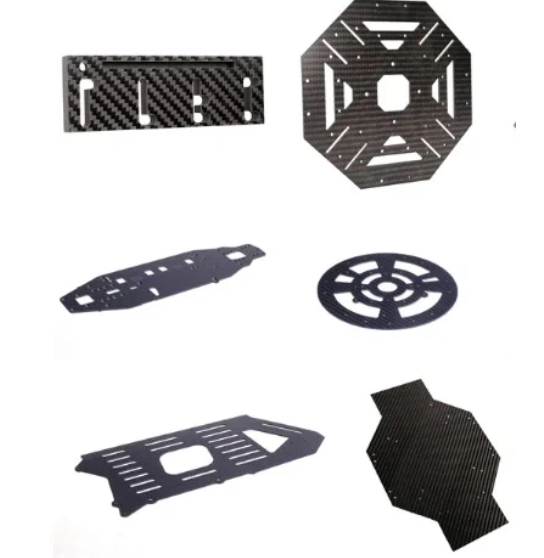

Types of Carbon Fiber Sheets

- Unidirectional (UD) Sheets: Aligned fibers for maximum strength in one direction.

- Woven Sheets: Cross-patterned fibers for balanced strength.

- Prepreg Sheets: Pre-impregnated with resin for easy composite manufacturing.

Maintenance and Care

Carbon fiber sheets require minimal maintenance. Regular cleaning with mild soap and avoiding abrasive materials ensures longevity. Always follow manufacturer guidelines for repairs.

Carbon fiber sheets are reshaping industries with their unmatched versatility. Whether in aerospace, automotive, or everyday tech, their lightweight strength and durability make them indispensable. Ready to explore how carbon fiber can elevate your project? Contact us for premium carbon fiber solutions tailored to your needs.