Carbon fiber sheets have revolutionized industries worldwide with their unparalleled combination of strength, lightness, and durability. As a trusted name in the industry, jiaxincarbonfiber.com is committed to providing in-depth insights into these advanced materials. In this comprehensive guide, we delve deeper into their composition, explore extended applications, and highlight why they stand out in modern manufacturing.

The Intricate Composition of Carbon Fiber Sheets

The exceptional properties of carbon fiber sheets stem from a meticulous manufacturing process and precise material selection. Let’s break down their composition:

1. Carbon Fiber Strands

The foundation lies in carbon fibers, which are produced from precursor materials. Polyacrylonitrile (PAN) is the most common precursor, accounting for over 90% of carbon fiber production, due to its ability to yield high-strength fibers. Other precursors include pitch (a byproduct of petroleum refining) and rayon, though these are less prevalent.

During production, precursors undergo stabilization (to prevent melting), carbonization (heating to 1,000–3,000°C in an oxygen-free environment to remove non-carbon elements), and sometimes graphitization (further heating to 2,500–3,000°C for enhanced crystallinity). This transforms the precursor into carbon fibers with a carbon content of 90–99%, boasting tensile strengths up to 7 GPa—far exceeding that of steel (around 0.2–2 GPa).

2. Matrix Resins

Carbon fibers alone are strong but brittle, so they are embedded in a matrix to form sheets. Epoxy resins are the most widely used due to their excellent adhesion, chemical resistance, and curing properties. Other matrices include polyester, vinyl ester, and phenolic resins, each tailored to specific applications: for example, phenolic resins are chosen for fire resistance in aerospace and automotive sectors.

3. Sheet Construction

Fibers are arranged in various patterns to create sheets:

- Unidirectional (UD) Sheets: Fibers aligned in a single direction for maximum strength along that axis, ideal for load-bearing structures.

- Woven Sheets: Fibers woven in crisscross patterns (e.g., 0°/90° or ±45°) for balanced strength in multiple directions, used in complex shapes like sports equipment.

- Multilayer Laminates: Combined UD and woven layers bonded together to achieve custom strength profiles, common in high-performance engineering.

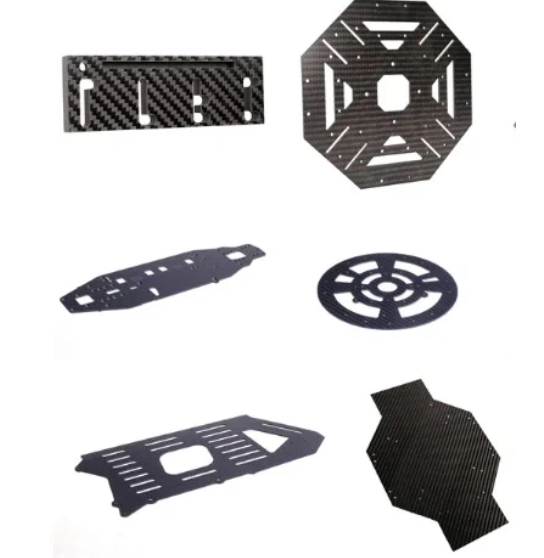

Expanded Applications Across Industries

Carbon fiber sheets’ versatility makes them indispensable in diverse sectors:

Aerospace & Defense

Beyond airframes and wings, they’re used in satellite components, missile casings, and drone structures. Their low thermal expansion ensures stability in extreme temperature fluctuations, critical for space missions.

Automotive & Racing

From luxury cars to Formula 1 vehicles, carbon fiber sheets reduce weight by up to 50% compared to steel, improving acceleration and fuel efficiency. They’re also used in battery enclosures for electric vehicles (EVs), enhancing safety and energy density.

Sports & Recreation

In addition to traditional gear, they’re integral to surfboards (for rigidity and buoyancy),(ski poles and cores for lightweight agility), and even rowing shells (for smooth water performance).

Construction & Infrastructure

Beyond bridges and buildings, they reinforce concrete in nuclear facilities (resisting radiation) and strengthen offshore oil platforms (withstanding saltwater corrosion).

Renewable Energy

Wind turbine blades use carbon fiber sheets to increase length without adding excessive weight, capturing more wind energy. They also reinforce solar panel frames, withstanding harsh weather conditions.

Medical & Healthcare

Prosthetic limbs made with carbon fiber sheets are lightweight and strong, improving mobility for users. They’re also used in MRI machines (non-magnetic properties) and surgical tools (sterilization resistance).

Why Carbon Fiber Sheets Outperform Traditional Materials

- Strength-to-Weight Ratio: 5x stronger than steel, 2x stronger than aluminum, but 30-50% lighter.

- Corrosion Resistance: Unaffected by moisture, chemicals, or UV rays, unlike metal.

- Fatigue Resistance: Maintains strength over repeated stress cycles, crucial for aircraft and machinery.

- Design Flexibility: Can be molded into complex shapes, enabling innovative product designs.

At jiaxincarbonfiber.com, we offer tailored carbon fiber sheet solutions, from standard sizes to custom laminates, backed by rigorous quality testing. Whether for industrial projects or specialized applications, our products deliver consistent performance.

Been using 718sp for a while now. Solid choice for a quick gaming session. Easy to navigate and find what you’re looking for. See More 718sp.

Subject: Follow-up on Your Inquiry About our product

Dear Valued Customer,

Hope this email finds you well! We noticed your recent inquiry about our Product via online channels, and we’d like to provide further support for your needs.

Our product is designed to improve work efficiency/reduce operational costs. and has been widely recognized by clients in the manufacturing. To help you better understand its fit for your business, we’ve prepared a detailed product brochure (attached below) with specs, case studies and pricing info.

Feel free to reach out if you have any questions—whether about technical details, customization options or a demo request. We’re also happy to schedule a 15-minute call at your convenience to walk you through key features.

Looking forward to your reply and assisting you further!

Best regards,

Liao yang jia xin carbide co ltd

Email : 3305317@163.com

Sprunki Game really takes music creation to the next level-it’s like Incredibox but with more depth and style. The expanded sound library and visual flair make composing feel fresh and exciting. Check it out at Sprunki Game!

Subject: Follow-up on Your Inquiry About our product

Dear Valued Customer,

Hope this email finds you well! We noticed your recent inquiry about our Product via online channels, and we’d like to provide further support for your needs.

Our product is designed to improve work efficiency/reduce operational costs. and has been widely recognized by clients in the manufacturing. To help you better understand its fit for your business, we’ve prepared a detailed product brochure (attached below) with specs, case studies and pricing info.

Feel free to reach out if you have any questions—whether about technical details, customization options or a demo request. We’re also happy to schedule a 15-minute call at your convenience to walk you through key features.

Looking forward to your reply and assisting you further!

Best regards,

Liao yang jia xin carbide co ltd

Email : 3305317@163.com