In the modern aerospace field, the choice of materials plays a decisive role in the performance of aircraft. Carbon fiber, this magical material, is shining brilliantly in the aerospace arena with its excellent properties.

Carbon fiber is a high-strength and high-modulus fiber with a carbon content of more than 90%. It has a series of excellent characteristics such as high strength, low density, high temperature resistance and fatigue resistance. Compared with traditional metal materials, carbon fiber has higher strength but is much lighter, making it an ideal choice for pursuing lightweight in the aerospace field. For example, its specific strength (the ratio of strength to density) is several times that of steel, and its specific modulus (an indicator to measure the elasticity of materials) is also quite excellent, which can significantly reduce the weight of the aircraft while ensuring structural strength.

Carbon fiber is widely used in aircraft manufacturing. In the early days, carbon fiber reinforced resin matrix composites were mainly used to make small non-load-bearing structures such as cabin doors, covers and fairings. With the development of technology, in the 1980s, they began to be used to make load-bearing and large-sized secondary load-bearing structural parts such as vertical tails, horizontal tails and canards. Nowadays, with the maturity of automatic placement technology and autoclave forming process, composite parts have gradually developed towards main load-bearing components with large force and size such as wings and fuselages.

Take the Boeing 787 as an example, the proportion of carbon fiber reinforced resin matrix composites used in its airframe is as high as 50%. The fuselage and wings are made of T800 grade carbon fiber toughened epoxy resin. This design can reduce air resistance, extend the service life of the airframe, improve fatigue strength and save fuel consumption during the operation of the aircraft. The mass of carbon fiber reinforced resin matrix composite structural parts in Airbus A-350 also exceeds 53%. Domestically, the COMAC C919 airliner uses carbon fiber reinforced resin matrix composites for its central wing, flaps and other components. Although its mass currently accounts for only 12% of the total mass of the aircraft structure, it also marks an important breakthrough in this field in China.

In terms of aero-engines, with the continuous improvement of engine performance requirements, especially the pursuit of weight reduction, carbon fiber composites have been more and more widely used. The use of composites can reduce the mass of fans and engines, and improve specific stiffness, fatigue performance, damage and defect tolerance. Compared with metal titanium alloy blades, the number of composite blades can be reduced by 50%, the mass can be reduced by 66%, and it has the advantages of high efficiency, low noise, low fuel consumption, strong vibration resistance and bird strike resistance.

In the aerospace field, carbon fiber also plays a key role. For intercontinental missiles, the nose cones and wing tips made of carbon fiber reinforced resin matrix composites have excellent thermodynamic properties and good heat insulation effect, which can maintain the aerodynamic shape of the aircraft and reduce non-guided errors. If the missile engine shell is made of this material, on the premise of meeting the weight reduction requirement, it can increase the range of the missile and achieve the goals of light weight, small volume and long range. In satellite structural parts, carbon fiber reinforced resin matrix composites have strong bearing capacity, save fuel while reducing weight, and have minimal deformation in high and low temperature environments. For example, many structures such as satellite solar cell arrays and antenna structures use carbon fiber composites.

With the continuous progress of aerospace technology, higher requirements have been put forward for the performance of carbon fiber materials. On the one hand, researchers are committed to further improving the performance of carbon fiber, such as strength and modulus; on the other hand, they are constantly optimizing its manufacturing process and reducing costs to improve the cost performance and application range of carbon fiber in the aerospace field. It is believed that in the future, carbon fiber will continue to play an important role in the aerospace field, helping mankind achieve greater achievements in the exploration of the sky and the universe.

That’s a great point about musical creativity being so accessible now! I’ve been playing around with Incredibox Sprunki – it’s surprisingly easy to make cool beats, even on mobile. Fun stuff! Really opens up music making to everyone.

Subject: Follow-up on Your Inquiry About our product

Dear Valued Customer,

Hope this email finds you well! We noticed your recent inquiry about our Product via online channels, and we’d like to provide further support for your needs.

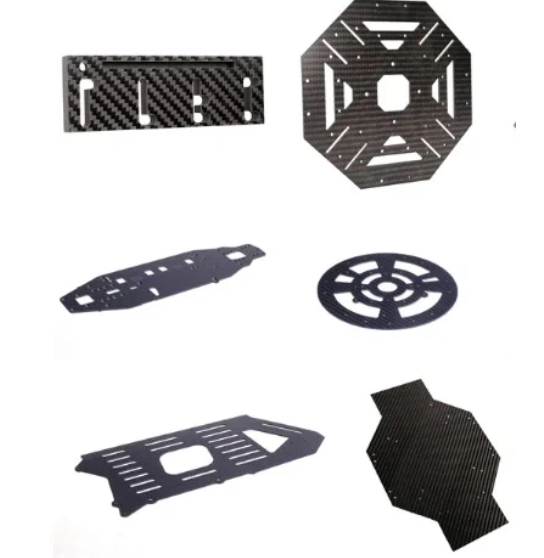

Our product is designed to improve work efficiency/reduce operational costs. and has been widely recognized by clients in the manufacturing. To help you better understand its fit for your business, we’ve prepared a detailed product brochure (attached below) with specs, case studies and pricing info.

Feel free to reach out if you have any questions—whether about technical details, customization options or a demo request. We’re also happy to schedule a 15-minute call at your convenience to walk you through key features.

Looking forward to your reply and assisting you further!

Best regards,

Liao yang jia xin carbide co ltd

Email : 3305317@163.com