In the vast realm of materials science, carbon fiber rods are becoming the “star materials” that are highly sought after in numerous fields due to their unique charm and outstanding performance. It not only subverts the performance boundaries of traditional materials, but also constantly explores the path of innovative applications, bringing many surprises to our lives and technological development.

Break through the traditional performance advantages

The most remarkable aspect of carbon fiber rods lies in their excellent strength-to-weight ratio. Compared with traditional metal materials, its weight is only about one fifth of that of steel, but it can provide tensile strength that is 8 to 10 times higher than that of ordinary steel, and its elastic modulus is also better than that of steel. This means that under the premise of ensuring structural strength, the use of carbon fiber rods can significantly reduce the weight of objects. For instance, in the aerospace field, carbon fiber rods are used as structural components in satellites and other aircraft, which can “travel light”, reduce launch energy consumption, enhance launch efficiency, and at the same time, in the complex space environment, they can operate stably and extend their service life due to their excellent corrosion resistance.

Precise and complex manufacturing processes

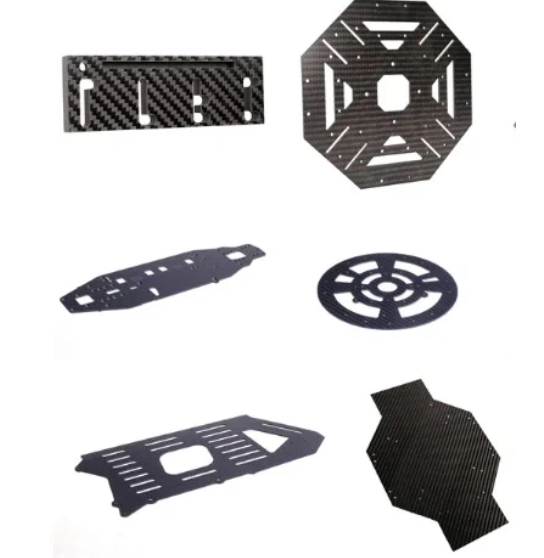

The birth of a high-quality carbon fiber rod requires going through many strict processes. First of all, the raw materials are carefully selected. Usually, high-quality carbon fiber filaments of 12K and 24K are chosen, and high-performance epoxy resin is combined to ensure product quality from the source. Subsequently, the carbon fiber filaments are immersed in the resin tank and evenly wrapped with resin, as if draped in a tough “armor”. This process endows the carbon fiber rods with excellent integrity and plasticity. Then, it is placed in a high-temperature mold at 130℃. The resin solidifies rapidly, and the carbon fiber filaments are “reborn” at high temperatures, precisely shaped into rods of the required size. Finally, the rods are precisely cut based on actual needs and undergo post-curing treatment to further optimize their performance, making each carbon fiber rod an outstanding “top student” with excellent performance.

A wide range of diverse application fields

Aerospace Field:

In addition to satellite structural components, carbon fiber rods are also widely used in rocket body structures, aircraft wings and other parts. Its lightweight and high-strength characteristics help reduce the overall weight of the aircraft and improve flight performance. In the aerospace field where ultimate weight reduction is pursued, it plays an irreplaceable role.

Sports Field

In addition to golf clubs and fishing rods, carbon fiber rods are also widely used in sports equipment such as tennis rackets, badminton rackets and bicycle frames. These devices not only provide athletes with a better user experience, but also help them break through their limits and achieve more outstanding results. For instance, a bicycle frame made of carbon fiber rods not only reduces the overall weight of the vehicle but also enhances the rigidity and comfort of the frame, making the ride smoother and more efficient

Building Reinforcement

For old Bridges and buildings, carbon fiber rods can be used to reinforce the structure through bonding, “injecting” new vitality into it. Compared with traditional reinforcement materials, carbon fiber rods have higher strength and better corrosion resistance, which can more efficiently and sustainably enhance the load-bearing capacity and stability of building structures, bringing new life to dilapidated buildings. In addition, in some large-span building structures, carbon fiber rods can be used as cables or supporting components to optimize the structural force, reduce the amount of steel used, and achieve lightweight and sustainable development of the building.

Expansion of emerging fields

With the rapid development of technology, carbon fiber rods have also emerged in emerging fields such as new energy vehicles and medical devices. In new energy vehicles, carbon fiber rods can be used to manufacture components such as body frames and battery trays, effectively reducing the weight of the vehicle body and increasing the vehicle’s driving range. In the field of medical devices, carbon fiber rods can be used to make precision parts such as surgical instruments and prosthetic limbs. Due to their non-magnetic, lightweight and high-strength properties, they can bring better treatment experiences and rehabilitation effects to patients. For instance, prosthetic limbs made of carbon fiber rods are not only lightweight and comfortable to wear, but also have good flexibility and strength, which can better simulate the movement of human limbs.

The innovative trend of carbon fiber rods

With the advancement of technology, the application and manufacturing techniques of carbon fiber rods are constantly innovating. Here are several trends worth noting:

1,Sustainability and environmental protection

The traditional manufacturing process of carbon fiber consumes a relatively high amount of energy. Researchers are exploring the use of bio-based resins and recyclable carbon fiber to reduce environmental impact. For instance, some companies have successfully developed carbon fiber rods made from plant fibers, significantly reducing their carbon footprint.

- Intelligence and functional integration

By embedding sensors or conductive fibers in carbon fiber rods, structural health monitoring and intelligent response functions can be achieved. For instance, smart carbon fiber rods can monitor the stress changes of Bridges in real time and provide early warnings of potential safety risks.

3,Nanotechnology enhancement

Combining carbon nanotubes or graphene with carbon fibers can further enhance the strength and electrical conductivity of the rods. This enhanced carbon fiber rod is expected to play a greater role in the next generation of aerospace and electronic devices.

4,Large-scale and low-cost production

With the advancement of automation technology and new material formulations, the production cost of carbon fiber rods is gradually decreasing. This will promote its popularization in the civilian field, such as household furniture, electric vehicle parts, etc.

Carbon fiber rods, as a disruptive material, are redefining standards in multiple industries. With the advancement of manufacturing technology and the reduction of costs, the application of carbon fiber rods will gradually expand from high-end fields to daily life. Imagine that in the future, cars might be entirely framed with carbon fiber rods, which are both lightweight and sturdy; Household ladders may be made of carbon fiber rods, which are both aesthetically pleasing and practical.

Carbon fiber rods, with their outstanding performance, wide application and innovative potential, are becoming an important force driving the development of various industries. From daily sports goods to high-end and cutting-edge fields such as aerospace and medical care, its presence is everywhere. With the continuous breakthroughs and innovations in technology, it is believed that carbon fiber rods will unlock more application scenarios and bring more unexpected changes to our world. On the path of pursuing lighter, stronger and smarter materials, carbon fiber rods are undoubtedly a brilliant star, leading the continuous development of materials science