In recent years, the field of unmanned aerial vehicles (UAVs) has witnessed remarkable growth and innovation, driven by their diverse applications in various sectors such as agriculture, photography, logistics, and military. A crucial factor contributing to the advancement of UAV technology is the selection of materials, and carbon fiber has emerged as a game – changer in this regard.

Carbon fiber is a high – performance material known for its exceptional strength – to – weight ratio. It is significantly lighter than traditional materials like aluminum and steel, while still offering superior strength. This characteristic makes it an ideal choice for UAV manufacturing, as UAVs require materials that can balance lightweight construction with high durability and structural integrity.

One of the primary applications of carbon fiber in UAVs is in the airframe construction. The airframe is the backbone of any UAV, and using carbon fiber allows for the creation of lightweight yet strong structures. This lightweight design not only enhances the UAV’s flight performance, such as increasing its payload capacity and extending its flight time, but also makes it more maneuverable. For example, in commercial drones used for aerial photography, a carbon fiber airframe enables the drone to carry high – quality cameras and other equipment without being weighed down, resulting in more stable and longer flights.

Carbon fiber is also widely used in the production of UAV wings. The wings need to be strong enough to support the UAV during flight while being flexible enough to withstand aerodynamic forces. Carbon fiber wings can be designed to have specific aerodynamic shapes, which improve the UAV’s lift and reduce drag. In military UAVs, which often operate in harsh environments and need to perform high – speed maneuvers, carbon fiber wings provide the necessary strength and durability to withstand extreme conditions.

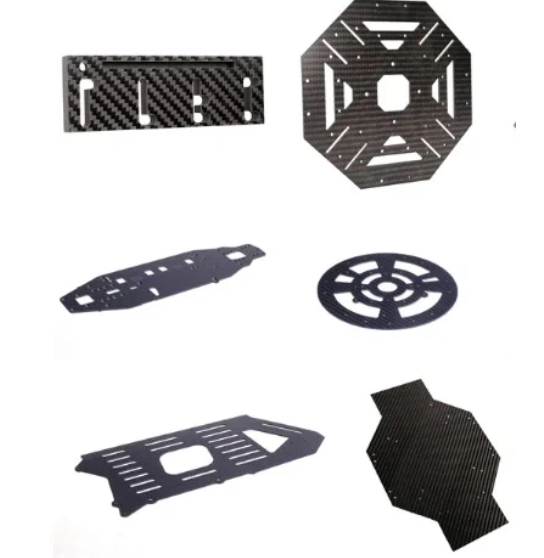

Another important application is in the production of UAV components such as propellers, landing gears, and control surfaces. Propellers made from carbon fiber are not only lightweight but also have high resistance to wear and tear, ensuring efficient and reliable operation. Landing gears constructed from carbon fiber are strong enough to absorb the impact during takeoff and landing, while also being lightweight to save energy. Control surfaces, which are essential for maneuvering the UAV, can be made more responsive and precise with carbon fiber, enhancing the overall flight control of the UAV.

The use of carbon fiber in UAVs also offers advantages in terms of corrosion resistance. Unlike metals, carbon fiber is not prone to rust or corrosion, making it suitable for UAVs that operate in humid, salty, or other corrosive environments. This extends the lifespan of the UAV and reduces maintenance costs.

In conclusion, carbon fiber materials have revolutionized the UAV industry by enabling the production of lightweight, strong, and durable UAVs. Their applications in airframe construction, wing design, and component production have significantly improved the performance and functionality of UAVs across various sectors. As the demand for UAVs continues to grow, the use of carbon fiber is expected to become even more prevalent, driving further innovation and advancements in UAV technology. If you are looking for high – quality carbon fiber materials for your UAV projects, visit jiaxincarbonfiber.com for a wide range of products and solutions.