Carbon fiber tubes have emerged as a versatile material in various industries, thanks to their exceptional combination of high strength, low weight, corrosion resistance, and rigidity. These properties make them indispensable in applications where performance, durability, and efficiency are paramount.

In the aerospace industry, carbon fiber tubes play a crucial role. Aircraft and spacecraft require components that can withstand extreme conditions while keeping weight to a minimum, and carbon fiber tubes fit the bill perfectly. They are used in the construction of structural elements such as wing spars, fuselages, and satellite frames. Their high strength-to-weight ratio reduces the overall mass of the vehicles, which in turn improves fuel efficiency and extends the range of aircraft. Additionally, their resistance to temperature fluctuations and harsh environments ensures the reliability and safety of aerospace equipment.

The automotive sector is another major user of carbon fiber tubes. As the industry shifts towards more fuel-efficient and high-performance vehicles, manufacturers are increasingly turning to lightweight materials. Carbon fiber tubes are employed in the production of various parts, including chassis components, drive shafts, and suspension systems. By replacing traditional metal parts with carbon fiber tubes, the weight of the vehicle is significantly reduced, leading to better acceleration, braking, and handling. Moreover, their stiffness helps enhance the structural integrity of the car, providing better protection for passengers in case of collisions.

Sports and recreation is a field where carbon fiber tubes have made a noticeable impact. In sports equipment, every gram counts, and the lightweight nature of carbon fiber tubes is a huge advantage. They are widely used in the manufacturing of bicycle frames, where they offer a perfect balance of strength and weight, allowing cyclists to ride faster and with less effort. Tennis rackets, golf clubs, and fishing rods also benefit from carbon fiber tubes, as they provide increased power and control. The material’s ability to absorb vibrations makes sports equipment more comfortable to use, reducing the risk of injury for athletes.

In industrial applications, carbon fiber tubes are valued for their durability and resistance to corrosion. They are used in the construction of machinery, such as robotic arms and conveyor systems, where their high strength ensures reliable operation even under heavy loads. In the renewable energy sector, carbon fiber tubes are utilized in wind turbine blades, helping to capture more energy by withstanding strong winds. Their resistance to chemicals also makes them suitable for use in chemical processing plants, where they can transport corrosive substances without degradation.

The marine industry also benefits from the use of carbon fiber tubes. Boat and yacht manufacturers use them in hulls, masts, and other structural components. The lightweight nature of carbon fiber tubes reduces the overall weight of the vessel, improving speed and fuel efficiency. Their resistance to water and salt corrosion ensures that they have a long lifespan, even in harsh marine environments. This makes them a cost-effective choice for marine applications in the long run.

In the medical field, carbon fiber tubes are finding increasing applications. They are used in the production of medical equipment such as patient beds, wheelchairs, and surgical instruments. The lightweight and strong properties of carbon fiber tubes make these devices easier to maneuver, improving the comfort and mobility of patients. Additionally, their non-magnetic nature makes them suitable for use in MRI rooms, where magnetic materials can interfere with the imaging process.

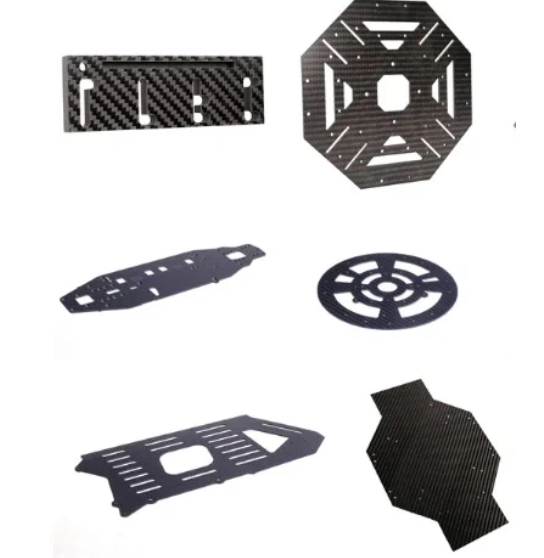

Furthermore, carbon fiber tubes are used in the construction of drones and unmanned aerial vehicles (UAVs). The lightweight design allows drones to have longer flight times and carry heavier payloads. Their rigidity ensures stability during flight, making them more reliable for various applications such as aerial photography, surveying, and delivery services. As the demand for drones continues to grow, the use of carbon fiber tubes in this field is expected to increase significantly.

In conclusion, carbon fiber tubes have a wide range of applications across various industries, from aerospace and automotive to sports, industrial, marine, medical, and drone manufacturing. Their unique combination of properties makes them an ideal material for applications where strength, lightweight, durability, and resistance to corrosion are essential. As technology continues to advance, it is likely that new applications for carbon fiber tubes will be discovered, further expanding their use in different fields.

Looking to gamble on the go? The 888slotapk is not bad . Works great on my Android. Some decent slots on there to lose your money, not as bad as the other gambling sites. Give it a go through 888slotapk!

Subject: Follow-up on Your Inquiry About our product

Dear Valued Customer,

Hope this email finds you well! We noticed your recent inquiry about our Product via online channels, and we’d like to provide further support for your needs.

Our product is designed to improve work efficiency/reduce operational costs. and has been widely recognized by clients in the manufacturing. To help you better understand its fit for your business, we’ve prepared a detailed product brochure (attached below) with specs, case studies and pricing info.

Feel free to reach out if you have any questions—whether about technical details, customization options or a demo request. We’re also happy to schedule a 15-minute call at your convenience to walk you through key features.

Looking forward to your reply and assisting you further!

Best regards,

Liao yang jia xin carbide co ltd

Email : 3305317@163.com