Ever wondered where those sleek, ultra-strong carbon fiber control arms end up? They’re not just shiny auto parts—they’re problem-solvers across industries that demand strength, lightness, and reliability. Let’s dive into where these lightweight wonders really shine, starting with the place most people connect with carbon fiber: cars.

First off, high-performance vehicles and motorsports are all about shaving weight without sacrificing durability, and carbon fiber control arms are a game-changer here. Think of sports cars or rally cars that need razor-sharp handling. Traditional steel or aluminum control arms add unnecessary bulk, which slows down acceleration and dulls responsiveness. Carbon fiber versions? They’re way lighter, letting the suspension move faster and more precisely. Race teams love them because every gram saved can mean milliseconds off lap times—a huge deal in competitive racing. But it’s not just about speed; luxury cars also benefit. Drivers of high-end vehicles want a smooth, quiet ride, and carbon fiber’s natural vibration-damping properties help reduce road noise and harshness, 提升 (oops, let’s keep it English!) enhancing that premium feel.

Electric vehicles (EVs) are another big fan of carbon fiber control arms. EVs already carry heavy battery packs, so reducing unsprung weight (the stuff that hangs below the suspension) is crucial for range and handling. Lighter control arms mean the motor doesn’t have to work as hard to move the wheels, improving efficiency. Plus, EVs are all about modern tech, and carbon fiber fits that sleek, advanced image. Mechanics also appreciate how these parts resist corrosion better than metal, especially in areas with harsh winters or salty roads—no more worrying about rust eating away at critical components.

But wait, it’s not just cars! Smaller vehicles like motorcycles and even electric scooters are hopping on the carbon fiber trend. Motorcycles need balanced handling to lean into turns safely, and lightweight control arms help with agility. For electric scooters, which are all about portability and battery life, every ounce saved matters for longer rides. Industrial machinery is another surprising field. Machines used in manufacturing or agriculture often need parts that can handle heavy loads without adding too much weight to the equipment itself. Carbon fiber control arms here mean less strain on the machine’s motor, longer lifespan for the equipment, and easier maintenance since they don’t rust or fatigue as quickly as metal counterparts.

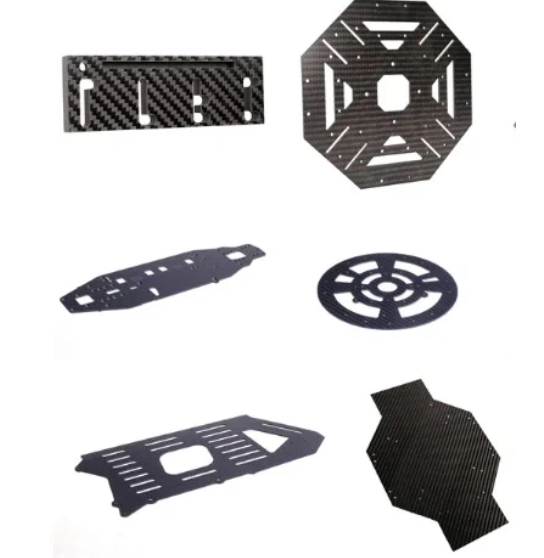

Aerospace and defense? Yep, they’ve been using carbon fiber for ages, and control arms in drones or small aircraft are no exception. Drones need to stay in the air as long as possible, so lightweight parts are non-negotiable. Carbon fiber’s strength keeps the drone stable in windy conditions, while its resistance to extreme temperatures is a must for high-altitude use. Even in defense applications, where equipment needs to be tough enough for rough terrain but portable for transport, carbon fiber control arms make logistics easier and performance more reliable.

So, whether it’s boosting speed on the track, improving efficiency in EVs, enhancing machinery durability, or enabling better flight in drones, carbon fiber control arms bring a mix of lightness, strength, and smart design to any field that values performance. They’re not just parts—they’re a upgrade that pays off in better handling, longer life, and even cost savings over time (thanks to less maintenance and improved efficiency). Ready to see how carbon fiber can transform your project? Explore high-quality carbon fiber control arms and more at jiaxincarbonfiber.com, where innovation meets real-world performance.