In the contemporary era of advanced material science, carbon fiber has emerged as a revolutionary material, extensively utilized across diverse industries. Its widespread adoption can be attributed to a unique combination of exceptional properties that surpass those of traditional materials, making it a preferred choice for engineers, designers, and manufacturers worldwide.

One of the most compelling reasons for the extensive use of carbon fiber is its remarkable strength to weight ratio. Carbon fiber is extremely lightweight, yet it boasts an incredibly high tensile strength. In fact, it is five times stronger than steel while being significantly lighter. This property makes it ideal for applications where minimizing weight without sacrificing structural integrity is crucial. For example, in the aerospace industry, the use of carbon fiber composites in aircraft construction has led to a substantial reduction in the overall weight of the aircraft. This weight reduction, in turn, results in lower fuel consumption, reduced emissions, and increased range. Boeing’s 787 Dreamliner is a prime example, with approximately 50% of its structure composed of carbon fiber composites, revolutionizing long – haul air travel.

Another key advantage of carbon fiber is its excellent durability and resistance to various environmental factors. It is highly resistant to corrosion, which is a significant problem for metals such as steel when exposed to moisture, chemicals, or saltwater. In marine applications, carbon fiber is used to construct boat hulls, masts, and rigging. Unlike traditional materials like aluminum or fiberglass, carbon fiber does not corrode, ensuring a longer lifespan for marine vessels and reducing maintenance costs. Additionally, carbon fiber has good fatigue resistance, meaning it can withstand repeated stress cycles without developing cracks or fractures. This makes it suitable for components that are subject to continuous vibrations and dynamic loads, such as wind turbine blades. Wind turbines operate in harsh outdoor environments and are constantly exposed to the forces of nature. Carbon fiber blades are able to endure these conditions for extended periods, contributing to the reliability and efficiency of wind energy generation.

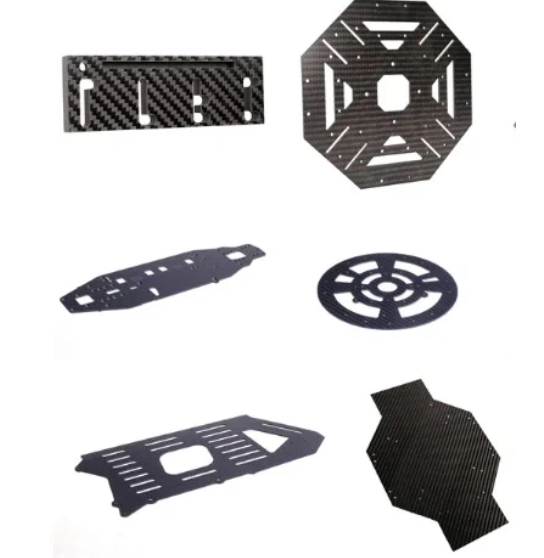

The versatility of carbon fiber also plays a major role in its widespread use. It can be combined with various matrices, such as polymers, ceramics, or metals, to create composite materials with tailored properties. These composites can be designed to meet specific requirements for different applications. For instance, in the automotive industry, carbon fiber composites are used to make body panels, chassis components, and engine parts. By using carbon fiber, automakers can achieve a lighter vehicle, which not only improves fuel efficiency but also enhances performance, such as acceleration and handling. High – performance sports cars like the Lamborghini Aventador and McLaren P1 extensively use carbon fiber components to achieve their remarkable speed and agility.

In the sports equipment industry, carbon fiber has transformed the way products are designed and perform. Tennis rackets, golf clubs, bicycles, and ski poles made from carbon fiber offer superior performance compared to their traditional counterparts. The high strength and low weight of carbon fiber allow for the creation of sports equipment that is more responsive, provides greater power transfer, and reduces the risk of injury due to its vibration – dampening properties. A carbon fiber tennis racket, for example, can generate more power with less effort, enabling players to hit the ball harder and with more precision.

Furthermore, carbon fiber has excellent thermal properties. It has a low coefficient of thermal expansion, which means it does not expand or contract significantly with changes in temperature. This property is essential in applications where dimensional stability is critical, such as in precision manufacturing equipment, telescopes, and satellite components. In space applications, where extreme temperature fluctuations are common, carbon fiber composites are used to construct satellite structures, ensuring that the delicate instruments on board remain properly aligned and function effectively.

The growing demand for sustainable and eco – friendly materials has also contributed to the popularity of carbon fiber. Although the production process of carbon fiber currently requires significant energy, research is underway to develop more sustainable manufacturing methods. Moreover, due to its durability and long lifespan, products made from carbon fiber often have a lower overall environmental impact compared to those made from materials that need frequent replacement. Additionally, carbon fiber can be recycled, and efforts are being made to improve the recycling processes to make them more efficient and cost – effective.

In conclusion, carbon fiber’s unique combination of high strength – to – weight ratio, durability, versatility, excellent thermal properties, and growing sustainability potential has led to its widespread adoption across numerous industries. As technology continues to advance and manufacturing costs decrease, it is likely that the use of carbon fiber will only continue to expand, driving innovation and transforming various sectors in the process.

That’s a great point about immersive experiences! It really elevates gameplay. I’ve been experimenting with music creation tools like Play Sprunki – instant access & no downloads make it super easy to jump in and get creative! Fun stuff.

Subject: Follow-up on Your Inquiry About our product

Dear Valued Customer,

Hope this email finds you well! We noticed your recent inquiry about our Product via online channels, and we’d like to provide further support for your needs.

Our product is designed to improve work efficiency/reduce operational costs. and has been widely recognized by clients in the manufacturing. To help you better understand its fit for your business, we’ve prepared a detailed product brochure (attached below) with specs, case studies and pricing info.

Feel free to reach out if you have any questions—whether about technical details, customization options or a demo request. We’re also happy to schedule a 15-minute call at your convenience to walk you through key features.

Looking forward to your reply and assisting you further!

Best regards,

Liao yang jia xin carbide co ltd

Email : 3305317@163.com